2020- Cable double end glue shell machine

|

With years of experience and exquisite technology in the wire harness processing industry, we have developed a fully automatic wire harness double end rubber shell threading machine, which was exhibited at the 2021 Shanghai Munich Exhibition and once again sparked industry discussions |

|

|

The COVID-19 broke out. In the fight against the epidemic, we developed an automatic production line of cup type mask machine, which can realize the functions of automatic forming, ear band welding, opening, breathing valve welding, cup body printing, breathing valve printing, and so on, and contribute its greatest value to the epidemic calming down |

|

|

|

2019- Multi line double end rubber shell Servo terminal crimping machine |

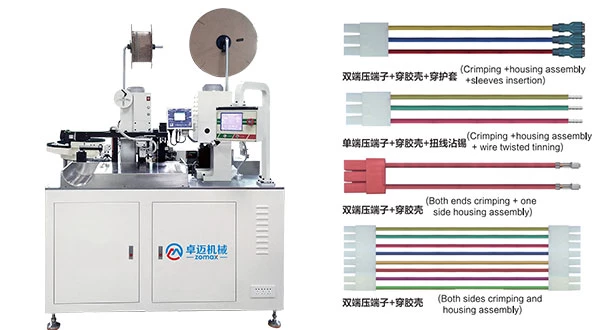

With continuous research and development efforts, a multi wire double end rubber shell terminal machine was launched in 2019, which can simultaneously cut, peel, press, and double end rubber shell multiple wires, greatly accelerating customer production |

|

|

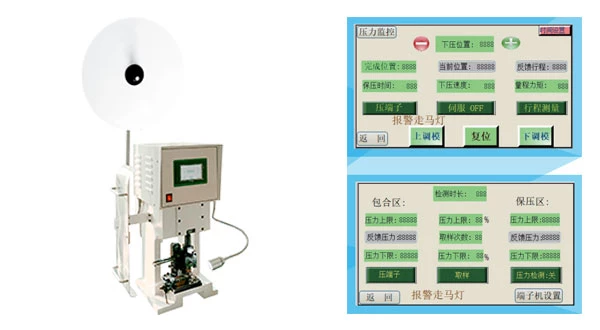

In response to the high cost of pressure management systems in the market, and based on customer needs, we have launched an intelligent servo terminal crimping machine (an intelligent terminal machine control system with pressure detection), which comes with pressure monitoring and accuracy comparable to imported pressure systems. It can detect two broken wires and has a higher cost-effectiveness |

|

|

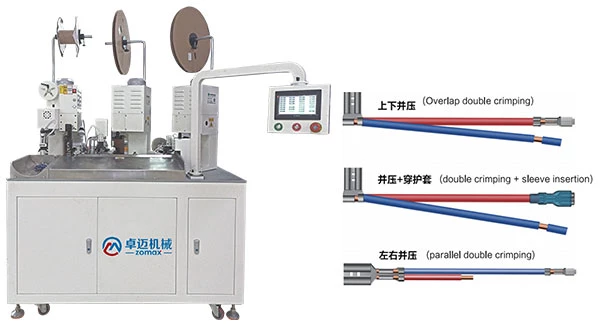

2018- Multi core wire terminal machine |

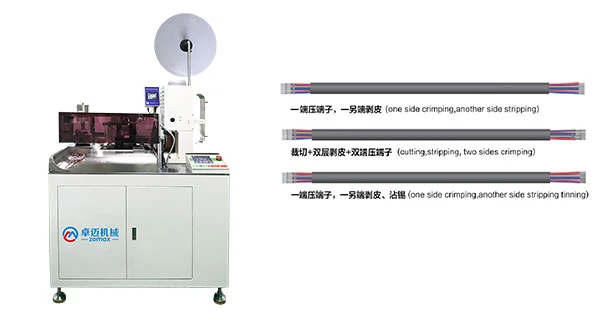

In 2018, a groundbreaking product was launched, the fully automatic multi-core wire (sheathed wire) terminal machine, which integrates the fully automatic cutting and peeling of the outer and inner layers of multi-core wires, followed by crimping of terminals or tin plated heat shrink tubing, solving the industry's long-standing problems |

|

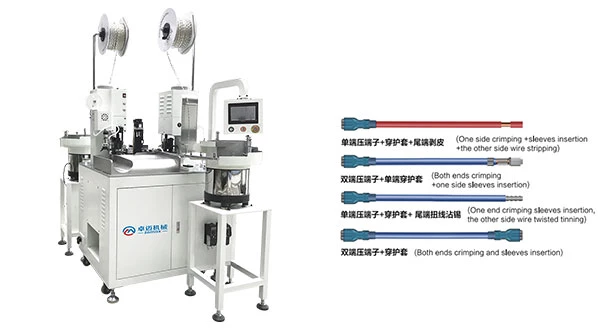

2017- Fully automatic rubber shell and sheath terminal machine |

Established in 2015 and showcased for the first time at the 2017 Shanghai Munich Electronic Equipment Exhibition, the rubber shell terminal machine was showcased. In September of the same year, it made a grand appearance at the Shenzhen Wire and Cable Exhibition, with one end wearing a protective sheath and the other end wearing a rubber shell terminal machine, causing a frenzy of discussion in the industry |

|

2016- Fully Automatic Number Tube Terminal Machine |

Combine the automatic coding machine/laser engraving machine with the automatic heat shrink tube terminal machine to achieve a fully automatic equipment that integrates automatic cutting, peeling, automatic pipe cutting, automatic coding, automatic positioning, and automatic baking, replacing multiple manual operation processes. Especially for products such as new energy vehicles, the high-quality solutions they bring have created enormous value. |

|

2015- Fully automatic heat shrink tubing terminal machine |

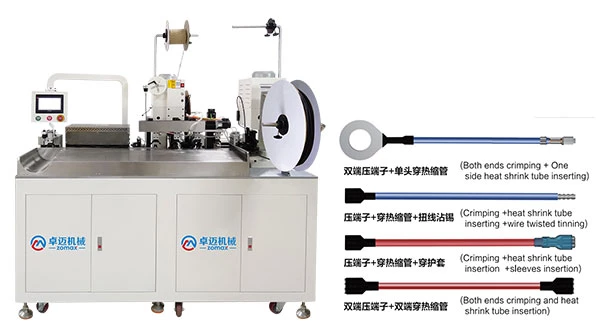

In 2015, the first fully automatic heat shrink tube terminal machine was launched, which gave hope to the industry's automatic heat shrink tube insertion. Heat shrink tube insertion is also very labor-intensive, and the industry mostly uses hot air blowing or boiling water. The demand for automatic heat shrink tube insertion machines in the industry is very urgent. After multiple improvements, double end heat shrink tube insertion was launched in 2016 and was recognized by customers |

|

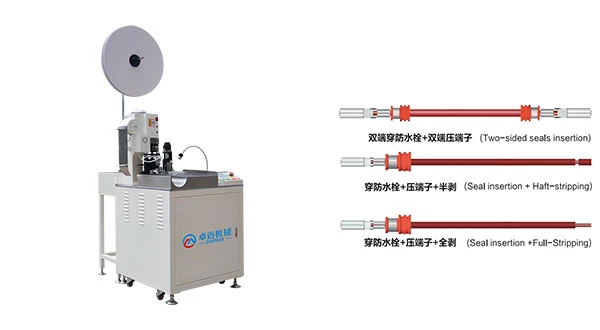

2014- Fully automatic waterproof plug terminal machine |

In response to the complex structure and high cost of waterproof plugs in the market, we take it lightly and simplify the structure, greatly reducing costs and saving customers real money and silver |

|

2013 Fully Automatic PVC Sheath Terminal Machine |

With the strong support of Gree's wire harness supply chain and the cooperation of sheath material manufacturers, we have successfully overcome the industry challenge of wearing PVC sheaths, broken through the automatic threading and pulling of sheaths, and liberated frontline employees from simple and repetitive labor. Today, we have successfully sold over 300 units |

|

2012 Flag Terminal Crimping Machine |

After 7 months of cooperation and assistance from collaborating manufacturers, we have successfully achieved automatic installation of flag shaped terminals, making it easy to change molds like regular terminal crimping, greatly improving efficiency and quality. |

|

2011- Double line crimping terminal machine |

In 2011, Zhuomai first launched a fully automatic dual line crimping terminal machine, which caused a sensation in the industry. Through practice, it continuously accumulated experience, matured its products, and paid great attention to quality and service, receiving unanimous praise from users. Since then, Zhuomai has established itself in the industry and achieved good development opportunities. |

|

Supplier of solution for wire harness processing equipment system